375th Anniversary of André-Charles Boulle‘s Birth.

On 11 November, 2017, the CEO of Jean Boulle Luxury presented a ‘Boulle Work‘ Jewellery Box to the Skipper of Partridge 1885 to commemorate Partridge’s fine wood Crafstmanship on the 375th Anniversary of André-Charles Boulle’s Birth, in 1642,. The unique, one-of-a-kind inlaid Boulle Box was made by the Curator and Ébéniste Yannick Chastang and is shown above on the left, alongside images of Partridge 1885 being rebuilt over a twenty-year period, testament to the craftsmanship and skill of the Partridge 1885 ébénistes involved.

Who was Andre-Charles Boulle?

André-Charles Boulle (11 November 1642 – 29 February 1732[1]), le joailler du meuble (the “marquetry jeweller”)[2], is the most famous French cabinetmaker and the preeminent artist in the field of marquetry [3][4], also known as “Inlay“[5]. Boulle was “the most remarkable of all French cabinetmakers”[6]. He was commended to Louis XIV of France, the “Sun King“, by Jean-Baptiste Colbert (29 August 1619 – 6 September 1683) as being “the most skilled craftsman in his profession”. Over the centuries since his death, his name and that of his family has been given to the art he perfected, the inlay of brass, tortoiseshell, brass and pewter into ebony. It is known as Boulle Work[7]and the École Boulle, a college of fine arts and crafts and applied arts in Paris, today bears testimony to his enduring art, the Art of inlay…. (…) André-Charles Boulle’s Protestant family environment was a rich and artistic milieu totally consistent with the genius of the Art he was to produce in later years. His father, Jean Boulle (ca 1616-?)[20], was cabinetmaker to the King, had been naturalised French in 1676 and lived in the Louvre, by Royal Decree. His grandather, Pierre Boulle (ca 1595-1649)[21], was naturalised French in 1675, had been cabinetmaker to Louis XIII and had also lived in the Louvre. André-Charles was thus exposed to two generations of illustrious artists, master craftsmen, engravers, cabinetmakers and, indeed, family all directly contracted by the King.

Source : https://en.wikipedia.org/wiki/Andr%C3%A9_Charles_Boulle

Source: https://www.andrecharlesboulle.com

Source: https://www.andrecharlesboulle.com/boulle-work/other

“Boulle Work“

Boulle Work is a marquetry process involving the inlay of brass, tortoiseshell, brass and pewter into ebony (or other exotic wood) which was perfected by André-Charles Boulle. ”Boulle’s inlay materials included tortoiseshell, brass, pewter and even animal horn. For contrasting woods, he often used rosewood, ebony, kingwood, and other dense, dark-toned tropical species. Boulle’s marquetry technique was to make two contrasting sheets of intricate inlay that were cut from a single sandwich of materials. If the sandwich, or packet, contained two layers that were light and dark, the two finalproducts would be a sheet with a light pattern on a dark background, and a reversed sheet, with a dark pattern on a light background. One sheet would have been considered the primary pattern, in French the ‘première partie’. The opposite pattern was called the counterpart, or ‘contrapartie’. By sawing both patterns out of one packet and reassembling them on two trays, the background of the ‘première partie’ becomes the motif of the ‘contrapartie’. Boulle made cabinets with both patterns in a single piece, or pairs of contrasting cabinets.”[37]

Tortoiseshell was used in thin sliced inlays onto wood and is today an important reference with regard to Boulle Work. Despite tortoiseshell’s rarity and cost, its durability, organic warmth and mottled-red aesthetics made it particularly apt for exotic wood such as ebony. This is because it gives a sense of depth to Boulle Work. The initial processing of tortoiseshell involves separating the layers of the scutes from the live animal’s carapace by heating, and softening the plates by boiling them, in salt water, and thereafter flattening them under a press. Although two pieces could be fused together by use of a hot iron, great care had to be taken not to lose the colour. Finishing and polishing was done by various techniques.[38][39]

Source: https://en.wikipedia.org/wiki/Andr%C3%A9_Charles_Boulle#Boulle_Work

Source: https://www.andrecharlesboulle.com

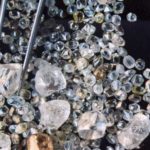

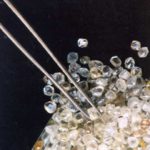

Marine Diamond Production by Diamond Fields Resources

Who is Jean-Raymond Boulle?

Jean-Raymond Boulle (born 1950) is the owner of Partridge 1885, founder of Diamond Fields Resources Inc. (which Inco purchased for US$4.3 billion), Diamond Fields International Ltd, America Mineral Fields Inc, and Titanium Resources Group Ltd, four publicly traded companies with deposits of nickel, cobalt, copper, zinc, titanium and diamonds.Boulle worked for the De Beers Diamond Trading Company (“DTC”) for ten years, in Zaire, Sierra Leone and Antwerp, Belgium, and then established Boulle Inc. in Dallas, Texas, US.

In 1984 he began exploring for diamonds, first in Minnesota, then in Arkansas.

In 1987 he formed Arkansas Diamond Development Co., to carry out exploration work on the Crater of Diamonds State Park in Arkansas.

Boulle was chairman, founder and CEO as well as a major shareholder of Diamond Fields (Diamond Fields Resources Inc. TSE:DFR) which commenced trading on the Vancouver Stock Exchange on April 6, 1993 and, in late 1994, discovered nickel, copper and cobalt ore bodies at Voisey’s Bay Mine in Labrador, Canada. The Voisey’s Bay Mine deposit was estimated to contain 141 million tonnes at 1.6% nickel. Boulle and Robert Friedland worked together in Diamond Fields and, in 1996, the Voisey’s Bay Mine Project was purchased by Inco for CND$4.3 billion.

Boulle’s next company, Diamond Fields International, is involved in sea floor mining with interests in mining deposits around the world.

The Boulle Mining Group is headquartered in Luxembourg and in 1995 founded American Mineral Fields (later renamed Adastra Minerals), listed on the London Stock Exchange’s Alternative Investment Market and the Toronto Stock Exchange. Adastra Minerals developed mining projects in the Democratic Republic of Congo and a joint venture with the government of the Democratic Republic of Congo to re-treat the Kolwezi tailings project. Adastra Minerals was purchased in August 2006 by First Quantum Minerals, a mining company then with dual listings on the Toronto Stock Exchange and the London Stock Exchange.

In 2001, Boulle Mining Group Luxembourg acquired the Sierra Rutile Project (a producer of natural rutile) and of the Sierra Minerals SML Bauxite Mine in Sierra Leone, West Africa which became part of Titanium Resources Group, taken public on the London Stock Exchange’s Alternative Investment Market in August 2005.

His mining group’s subsidiary company, Greenland Gold Resources Ltd is in Greenland exploring for nickel, copper, cobalt, platinum group elements, titanium and graphite.

Boulle Mining Group Luxembourg was the largest shareholder in World Titanium Resources, the Australian Securities Exchange listed discoverers and owners of the Toliara Sands titanium deposit in Madagascar. World Titanium Resources was delisted from ASX on 30 January 2017 and is now privately owned as World Titane Holdings Limited.

Together with the Government of Mauritius, Boulle is one of the three controlling shareholders of Omnicane, a publicly listed company on the Stock Exchange of Mauritius. Omnicane owns sugarcane plantations in Mauritius and produces refined sugar. Omnicane also generates around 30% of the island’s electricity for the Grid and 40% of the country’s renewable bagasse-based energy.

Boulle’s companies have conducted mining and exploration operations for gold, copper, nickel, zinc, and diamonds and other precious and semi-precious stones in South Africa, Namibia, Liberia, Madagascar, Democratic Republic of Congo, Zambia, Finland, Canada, and Brazil.

Since 1996, Boulle has made numerous ongoing donations and contributions to charity, hospitals, museums, animal conservation, bird conservation and to the World Wide Fund For Nature.

In 2007, Boulle was made a Commander of the Order of the Rokel, one of the highest orders of merit of Sierra Leone. This was given by the country of Sierra Leone, in recognition, for having restarted the economy of Sierra Leone with a titanium and a bauxite mine.

On 2 December 2014, the Boulle Group’s Tendyne Holdings Inc. start-up company announced the world’s first successful Human Heart Mitral Valve implants at the Royal Brompton Hospital in London, England.

In September 2015, Jean Boulle Medtech Ltd, a founding investor of Tendyne, announced that Abbott Laboratories (NYSE: ABT) had closed its acquisition of Tendyne.Abbott Laboratoriesthereby acquired the remaining shares of Tendyne it did not already own for US$250 million plus US$150 million in potential future payments tied to regulatory milestones. This acquisition culminated a relationship that began when Jean Boulle Medtech welcomed Abbott Laboratories as an early strategic investor in Tendyne. Jean Boulle Medtech worked with Tendyne’s most recent investor, Apple Tree Partners, in helping to complete the transaction.

In March 2016, the Jean Boulle Luxury Group announced the launch of its patent-pending, proprietary Sun KingTM diamond compound for luxury finishes, and confirmed the delivery of the first car with this finish.

In March 2017, the Jean Boulle Luxury Group announced that its patent-pending Sun KingTM luxury diamond finish technology had been used in a paint exhibited on a Rolls-Royce Ghost Elegance (EWB) at the 2017 Geneva Motor Show.

In April 2017, the Jean Boulle Luxury Group announced that the technology had been applied to a classic Pininfarina-styled Bentley, the Bentley Azure exhibited at the Top Marques Monaco Super Car show.

On 11 May 2017, the group signed an agreement with AkzoNobel for the production of its aviation grade Sun KingTM Diamond Coating for the private and commercial jet markets.

On 22 May 2017, the group launched the world’s first aircraft finished with Sun King diamond coating (produced by AkzoNobel in Holland) at EBACE 2017 in Geneva, the first to be covered in natural gem diamonds onto an ultra long-range Bombardier Aerospace Global Express.